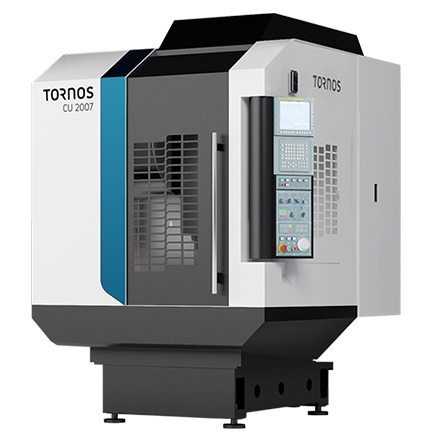

The gateway to 3-7-axis machining

The CU 2007 and CU 3007 combine dynamic performance and outstanding reliability with Swiss expertise, enabling Tornos to offer its customers a truly innovative solution. The comprehensive standard equipment, combined with the expertise of the company’s engineers, create the optimal conditions for producing complex workpieces.

Main advantages

- High-performance 3-7*-axis machining

- Ultra-quick tool changes

- Different integrated automation systems depending on the workpiece requirements

- External robotisation on request

- Machining of short bars up to Ø 27 mm

- 60 m/min rapid feed rate

- Spindle up to 40,000 rpm

- Throughspindle cooling

Types of workpiece

- Secondary machining of series parts

- Medical

- Connectors

- Watchmaking

- Automotive

- Luxury

*Option

Pick and place System (option): Automation of the production on CU 2007/3007

Technical characteristics | CU 2007 | CU 3007 | |

|---|---|---|---|

X-axis | mm | 500 | 700 |

Y-axis | mm | 400 | 400 |

Z-axis | mm | 470 | 470 |

Tool magazine (position) | 16 / 24 / 40* | 16 / 24 / 40* | |

Tool Holder | HSK-E40 | HSK-E40 | |

Chip-to-chip time | sec. | < 3 | < 3 |

Spindle | rpm | 12’000, 20’000* or 40’000* | 12’000, 20’000* or 40’000* |

Table size | mm | 650 x 400 | 850 x 400 |

Dimensions L x W x H | mm | 1580 x 2450 x 2410 | 2100 x 2450 x 2410 |

Control type | Fanuc 0iMD / 31iB* | Fanuc 0iMD / 31iB* | |

5-axis simultaneous (option) | FANUC 31iB-5* | FANUC 31iB-5* |

*Option